Day 3: Enhancing Connectivity with Micro Circular Connectors in Industrial Applications

2024-09-07

Day 3: Enhancing Connectivity with Micro Circular Connectors in Industrial Applications

Table of Contents

- 1. Introduction to Micro Circular Connectors

- 2. Understanding Micro Circular Connectors

- 3. Benefits of Using Micro Circular Connectors

- 4. Applications in Industrial Settings

- 5. Design Considerations for Micro Circular Connectors

- 6. Best Practices for Implementation

- 7. Troubleshooting and Maintenance

- 8. Future Trends in Connectivity

- 9. FAQs about Micro Circular Connectors

- 10. Conclusion

1. Introduction to Micro Circular Connectors

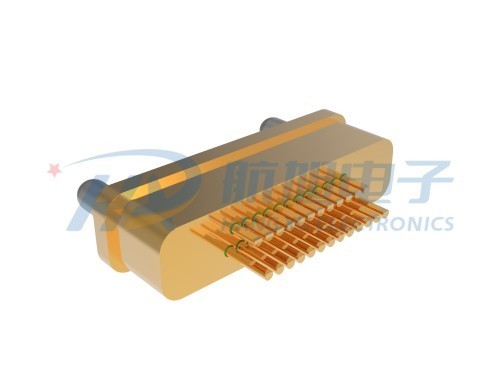

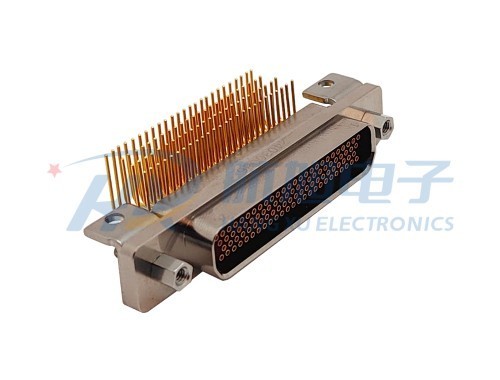

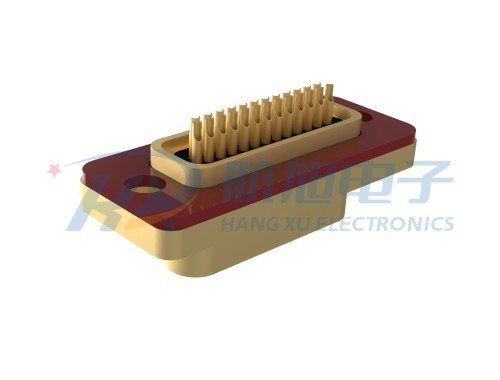

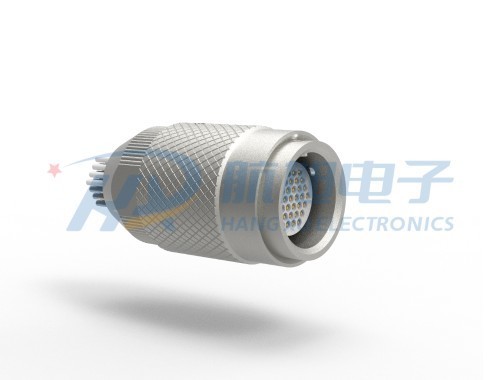

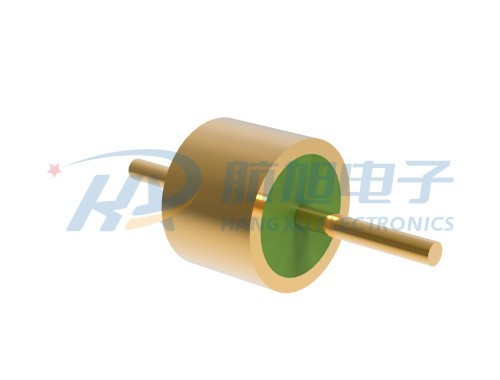

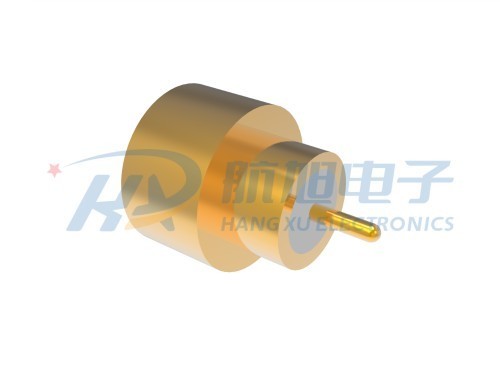

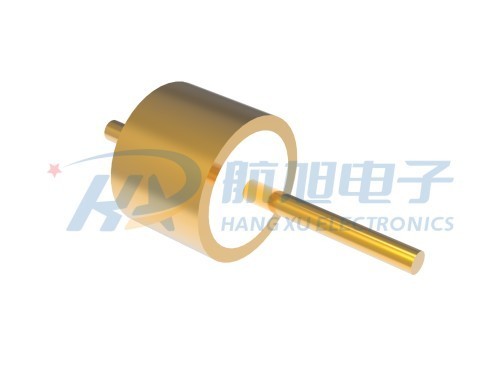

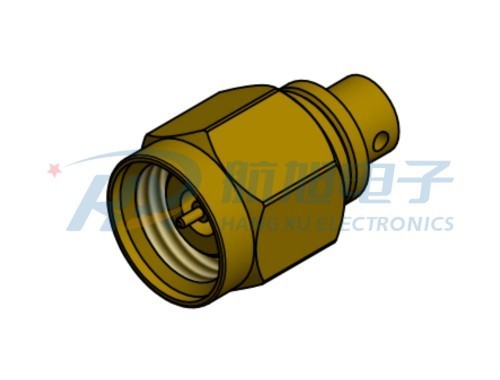

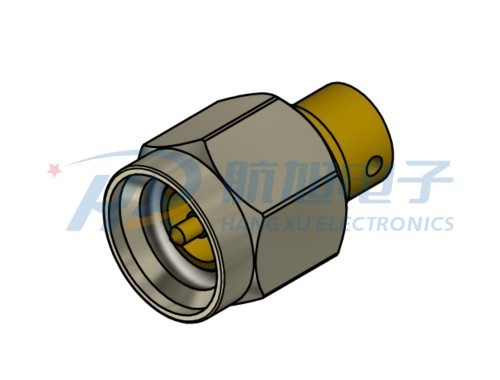

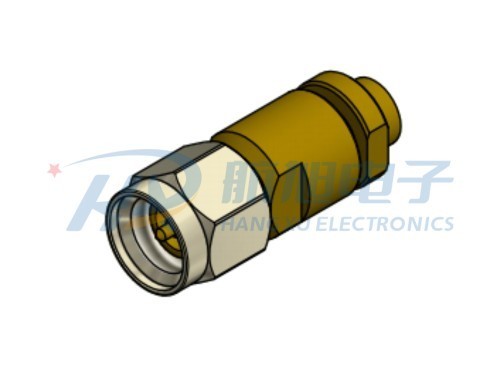

In today’s rapidly evolving industrial landscape, the demand for reliable and efficient connectivity solutions is paramount. **Micro circular connectors** have emerged as a key player in this arena, offering a compact design and robust performance. These connectors are particularly well-suited for environments where space is limited and durability is essential. This article delves into the significance of micro circular connectors in enhancing connectivity for various industrial applications, providing insights on their benefits, design considerations, and future trends.

2. Understanding Micro Circular Connectors

Micro circular connectors are designed to facilitate electrical connections in compact spaces. These connectors feature a circular design, which not only contributes to their compactness but also ensures a secure and reliable connection. Typically made from high-quality materials, micro circular connectors are engineered to withstand harsh environments, making them ideal for industrial settings.

Key Features of Micro Circular Connectors

- **Compact Size**: Their small footprint allows for use in limited spaces without compromising performance.

- **Durability**: Designed to endure extreme temperatures, vibrations, and exposure to moisture, these connectors are built for longevity.

- **Versatility**: They can be utilized in a variety of applications, from robotics to telecommunications, thanks to their adaptable design.

3. Benefits of Using Micro Circular Connectors

The integration of micro circular connectors in industrial applications offers numerous advantages:

Enhanced Connectivity

Micro circular connectors provide reliable connections that enhance the overall efficiency of electrical systems. Their secure locking mechanisms ensure that connections remain intact even in demanding environments.

Space Efficiency

In industries where space is often at a premium, micro circular connectors offer a solution that maximizes functionality while minimizing space requirements. Their compact size does not compromise their performance, making them an ideal choice for a wide range of applications.

Reduced Weight

The lightweight nature of micro circular connectors contributes to the overall efficiency of machinery and equipment. Reducing the weight of connections can lead to improved energy efficiency and performance.

4. Applications in Industrial Settings

Micro circular connectors find applications across various industrial sectors, including:

Robotics

In robotics, micro circular connectors are essential for connecting sensors, actuators, and other components. Their durability and compactness are critical in optimizing robotic designs for performance and efficiency.

Telecommunications

The telecommunications industry relies heavily on micro circular connectors to ensure stable connections in communication devices. Their ability to withstand environmental challenges makes them suitable for outdoor installations.

Aerospace

In aerospace applications, micro circular connectors play a vital role in ensuring reliability and safety. They are used in avionics, satellite systems, and other critical applications where failure is not an option.

Medical Devices

Micro circular connectors are also increasingly used in medical devices, providing reliable connections in compact spaces. Their durability and resistance to moisture make them ideal for environments where hygiene is paramount.

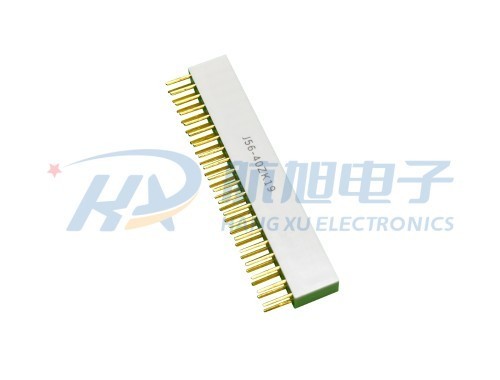

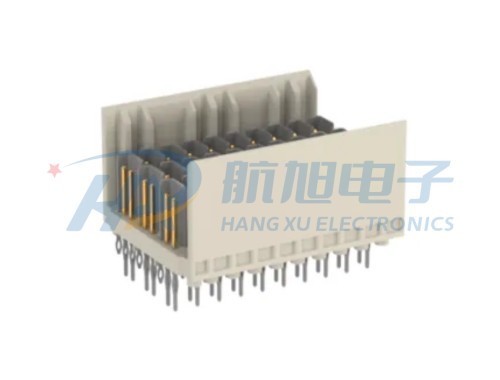

5. Design Considerations for Micro Circular Connectors

When designing or selecting micro circular connectors for industrial applications, several factors should be considered:

Material Selection

The choice of materials is crucial in ensuring the durability of connectors. High-grade materials such as stainless steel and thermoplastics are commonly used for their resistance to corrosion and wear.

Size and Weight Specifications

It's essential to consider the size and weight specifications of micro circular connectors to ensure they fit the intended application without adding unnecessary bulk.

Environmental Resistance

Given the often harsh conditions in industrial settings, connectors should be designed to withstand extreme temperatures, moisture, and other environmental factors.

6. Best Practices for Implementation

To ensure optimal performance of micro circular connectors in industrial applications, follow these best practices:

Proper Installation

Ensure that connectors are installed correctly to prevent issues such as loose connections, which can lead to system failures. Following manufacturer guidelines during installation is essential.

Regular Inspections

Conduct regular inspections of connectors to identify any signs of wear or damage. Early detection of issues can prevent costly downtime and repairs.

Environmental Monitoring

Regularly monitor the environmental conditions in which the connectors operate. Ensuring that connectors are maintained in suitable conditions will prolong their lifespan and functionality.

7. Troubleshooting and Maintenance

Addressing issues with micro circular connectors requires a systematic approach:

Common Issues

- **Intermittent Connectivity**: This may result from loose connections or damage to the connectors. Check for proper installation and physical integrity.

- **Corrosion**: Exposure to moisture can lead to corrosion. Ensure connectors are adequately sealed and consider using corrosion-resistant materials.

Maintenance Practices

Regular maintenance practices, such as cleaning connectors and ensuring proper environmental conditions, can significantly enhance the longevity and reliability of micro circular connectors.

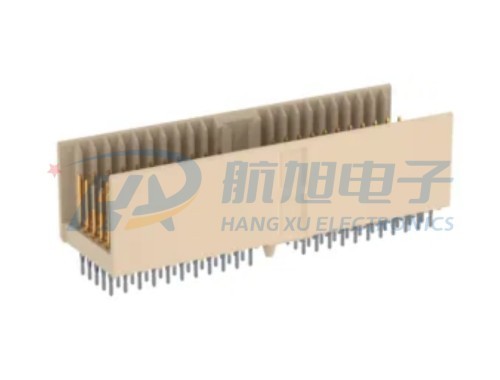

8. Future Trends in Connectivity

As technology continues to evolve, so do the demands for connectivity solutions. Emerging trends in micro circular connectors include:

Increased Miniaturization

As industries strive for more compact and efficient designs, the trend towards miniaturization of connectors is set to rise. Micro circular connectors will evolve to meet these demands without sacrificing performance.

Smart Connectors

The integration of smart technology into connectors will enable real-time monitoring and diagnostics, providing enhanced functionality and reliability in industrial applications.

9. FAQs about Micro Circular Connectors

What are micro circular connectors used for?

Micro circular connectors are used in various applications including robotics, telecommunications, aerospace, and medical devices to ensure reliable and compact electrical connections.

How do I choose the right micro circular connector?

When selecting a micro circular connector, consider factors such as material, size, environmental resistance, and application-specific requirements.

Can micro circular connectors withstand harsh environments?

Yes, micro circular connectors are designed to withstand extreme temperatures, moisture, and vibrations, making them suitable for harsh industrial environments.

What maintenance is required for micro circular connectors?

Regular inspections, cleaning, and monitoring of environmental conditions are essential for maintaining the performance and longevity of micro circular connectors.

Are micro circular connectors customizable?

Many manufacturers offer customizable options for micro circular connectors to fit specific application needs, including variations in size, shape, and materials.

10. Conclusion

Micro circular connectors play an essential role in enhancing connectivity across various industrial applications. Their compact design, durability, and reliability make them an ideal choice for industries facing ever-increasing demands for efficient and effective electrical connections. As technology continues to evolve, the importance of these connectors will only grow, leading to innovations that promise to further enhance their capabilities and applications. By understanding their benefits, applications, and best practices, industries can leverage micro circular connectors to optimize their connectivity solutions and drive greater operational efficiency.

Related Documents

Related News