Empowering Your Electrical Systems with Gas Sealed Micro-D Connectors

2024-09-09

Empowering Your Electrical Systems with Gas Sealed Micro-D Connectors

Table of Contents

1. Introduction to Gas Sealed Micro-D Connectors

2. The Importance of Reliable Electrical Connections

3. What Makes Gas Sealed Micro-D Connectors Unique?

3.1 Design and Construction

3.2 Performance Capabilities

4. Applications of Gas Sealed Micro-D Connectors

4.1 Aerospace Industry

4.2 Military and Defense

4.3 Industrial Applications

5. Benefits of Using Gas Sealed Micro-D Connectors

5.1 Environmental Protection

5.2 Enhanced Signal Integrity

5.3 Space-Saving Design

6. Choosing the Right Gas Sealed Micro-D Connector

6.1 Key Considerations

6.2 Compatibility and Standards

7. Installation and Maintenance Tips

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Gas Sealed Micro-D Connectors

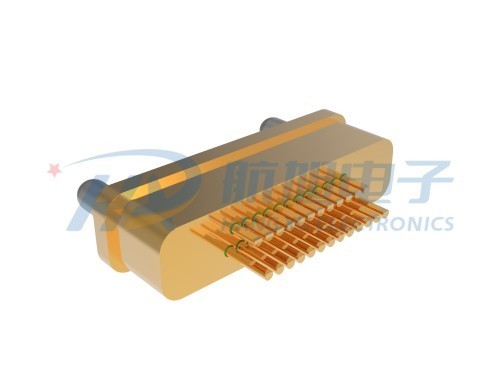

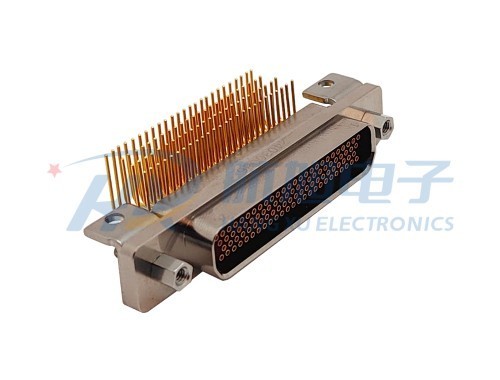

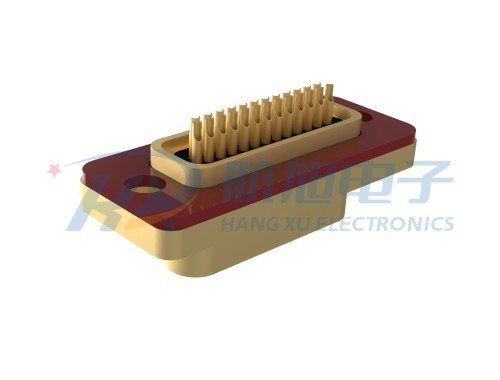

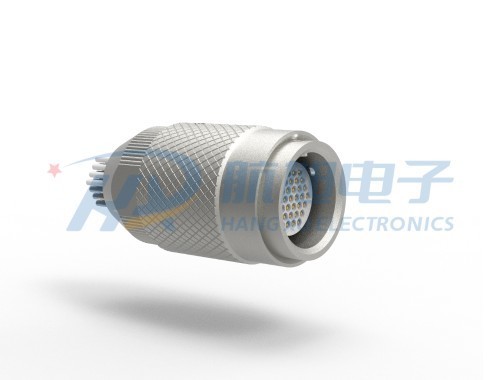

Gas Sealed Micro-D Connectors are a vital component in the electrical connectivity landscape, designed to offer superior performance in challenging environments. These specialized connectors ensure that electrical systems remain operational, no matter the external conditions. With applications across various industries, including aerospace, military, and industrial sectors, their importance can hardly be overstated.

2. The Importance of Reliable Electrical Connections

In today’s technology-driven world, reliable electrical connections form the backbone of operational efficiency. Poor connections can lead to downtime, decreased performance, and increased repair costs. Therefore, choosing high-quality connectors is essential for any application where reliability is paramount. This is where Gas Sealed Micro-D Connectors shine, providing a dependable solution for critical systems.

3. What Makes Gas Sealed Micro-D Connectors Unique?

Gas Sealed Micro-D Connectors stand out due to their innovative design and robust construction. Let's delve deeper into what makes these connectors a preferred choice.

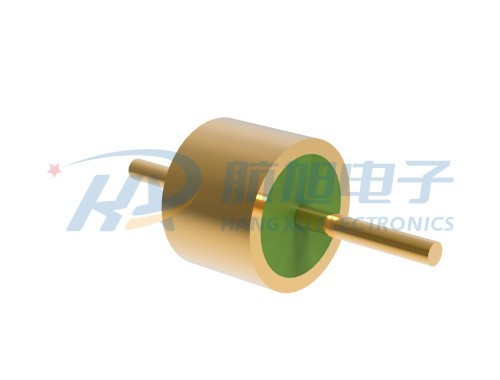

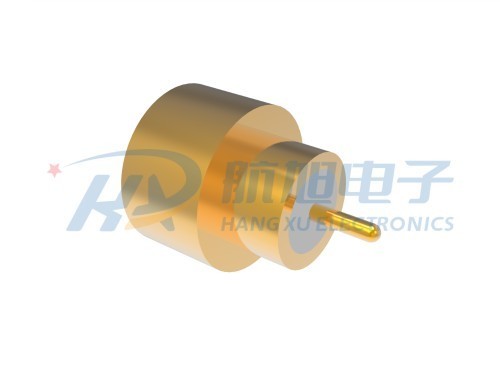

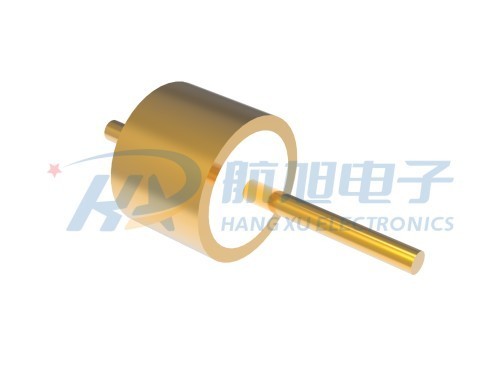

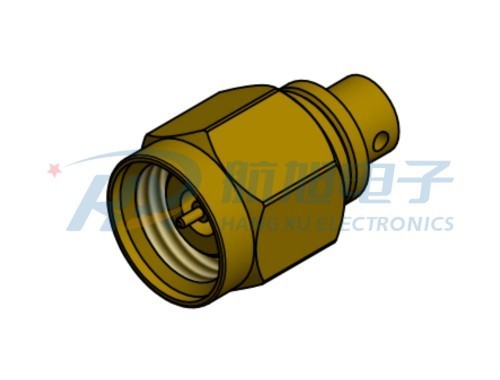

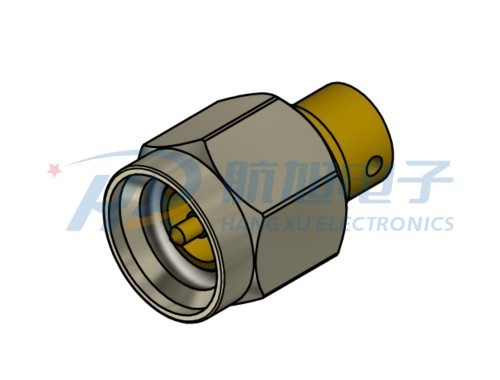

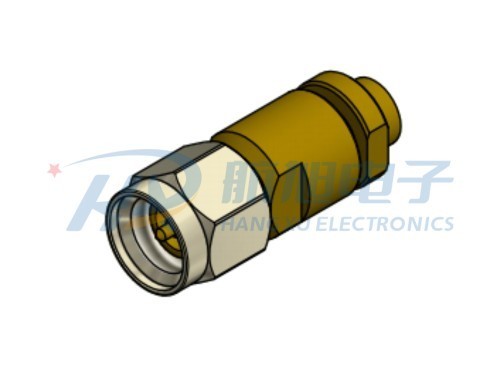

3.1 Design and Construction

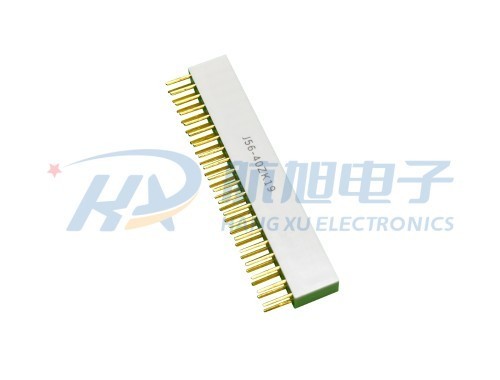

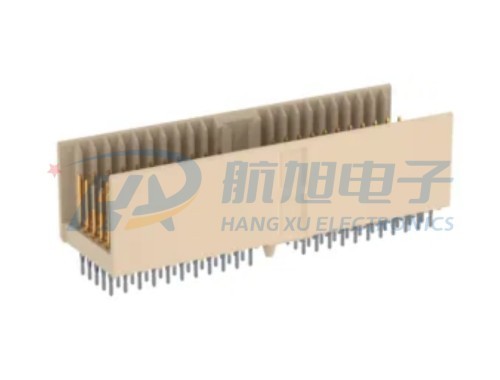

The design of Gas Sealed Micro-D Connectors incorporates a compact format, allowing them to fit into spaces where traditional connectors might not. Their robust materials contribute to their durability, making them resistant to environmental factors such as moisture and dust. The unique sealing mechanism further enhances their capability to prevent contaminants from entering the connector, thus maintaining optimal performance.

3.2 Performance Capabilities

These connectors are engineered to operate effectively even in the most demanding conditions. They offer reliable performance in extreme temperatures, vibrations, and pressures, ensuring that electrical connections remain intact and functional. The application of gas sealing technology significantly reduces the risk of signal loss and enhances the overall integrity of the connection.

4. Applications of Gas Sealed Micro-D Connectors

Gas Sealed Micro-D Connectors are versatile and widely used across various industries. Here are some prominent applications.

4.1 Aerospace Industry

In the aerospace sector, the reliability of connectors is non-negotiable. Gas Sealed Micro-D Connectors are extensively used in aircraft systems, avionics, and space applications. Their ability to withstand extreme conditions while maintaining performance is crucial for ensuring the safety and efficiency of airborne systems.

4.2 Military and Defense

Military applications demand connectors that can survive harsh environments. Gas Sealed Micro-D Connectors meet these needs, providing the robustness required for military avionics, communication systems, and weaponry. Their reliability in critical missions ensures that equipment functions effectively without failure.

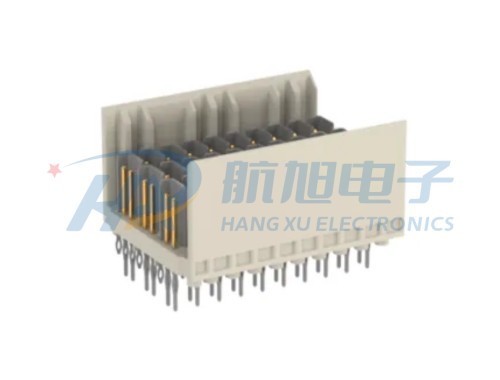

4.3 Industrial Applications

In industrial settings, Gas Sealed Micro-D Connectors find use in automation, robotics, and heavy machinery. Their compact design and robust performance make them ideal for applications where space is limited, yet reliability is essential. These connectors can help reduce downtime and maintenance costs due to their durability.

5. Benefits of Using Gas Sealed Micro-D Connectors

The adoption of Gas Sealed Micro-D Connectors comes with numerous advantages:

5.1 Environmental Protection

These connectors are designed to provide excellent environmental sealing, protecting against moisture, dirt, and other contaminants that could compromise electrical performance. This feature is particularly beneficial in outdoor and industrial applications.

5.2 Enhanced Signal Integrity

Gas Sealed Micro-D Connectors excel in maintaining signal integrity. The secure connection minimizes the risk of signal loss and ensures that data transmission remains clear and uninterrupted, which is crucial for communication systems.

5.3 Space-Saving Design

Their compact design makes them an ideal choice for applications where space is at a premium. By utilizing Gas Sealed Micro-D Connectors, engineers can achieve more efficient designs without sacrificing performance.

6. Choosing the Right Gas Sealed Micro-D Connector

Selecting the appropriate Gas Sealed Micro-D Connector for your application is critical. Here’s what to consider.

6.1 Key Considerations

When choosing a connector, assess the required specifications, including current and voltage ratings, environmental sealing requirements, and mechanical durability. Understanding the specific needs of your application will guide you in selecting the right connector.

6.2 Compatibility and Standards

Ensure that the connectors you choose comply with industry standards. Compatibility with the existing systems is also vital for seamless integration. Review datasheets and consult with manufacturers to confirm specifications.

7. Installation and Maintenance Tips

Proper installation and maintenance of Gas Sealed Micro-D Connectors are essential for optimal performance.

First, ensure that the connectors are installed according to the manufacturer’s guidelines. This may involve specific torque settings, alignment procedures, and environmental considerations. Regular inspections should also be performed to check for signs of wear or damage, ensuring that any potential issues are addressed before they lead to failures.

8. Frequently Asked Questions (FAQs)

What is the primary advantage of Gas Sealed Micro-D Connectors?

The primary advantage is their ability to provide reliable electrical connections in harsh environments, protecting against moisture, contaminants, and extreme temperatures.

Are Gas Sealed Micro-D Connectors suitable for high-frequency applications?

Yes, these connectors are designed to maintain signal integrity, making them suitable for high-frequency applications.

What industries primarily use Gas Sealed Micro-D Connectors?

They are widely used in aerospace, military, industrial automation, and robotics.

How do I know if a Gas Sealed Micro-D Connector is compatible with my system?

Check the specifications for current, voltage ratings, and compatibility with industry standards to ensure proper integration.

What maintenance is required for Gas Sealed Micro-D Connectors?

Regular inspections for wear and damage, along with ensuring proper installation, are key to maintaining performance.

9. Conclusion

Gas Sealed Micro-D Connectors are indispensable in empowering electrical systems across various applications. Their unique features, such as environmental protection, compact design, and enhanced signal integrity, make them ideal for industries where reliability is crucial. By choosing the right connector and ensuring proper installation and maintenance, you can significantly enhance your system's performance and longevity. Investing in high-quality connectors like Gas Sealed Micro-D not only safeguards your operations but also drives efficiency and innovation across your projects.

Related Documents

Related News